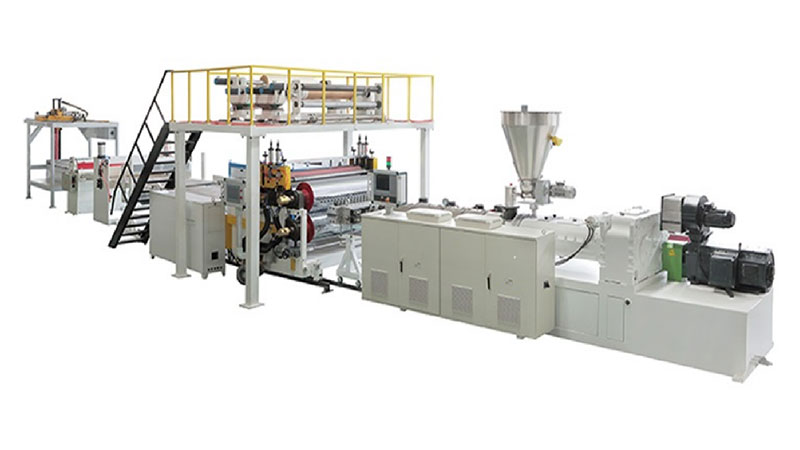

Mixing & Extrusion Equipment for SPC Flooring Production

Stone Plastic Composite (SPC) Flooring Making Machine

The mixing and extrusion equipment for SPC flooring production involves a high speed heater mixer and extrusion equipment.

Desired for its plastic forming capabilities, this mixer is widely used for combining PVC and resin, coloring and integrating polyethylene and polypropylene granules, and also pre-drying wet resin compositions. The mixed raw material is fed into an extruder, forming it into sheets which are hot-pressed with a wear-resistant layer and color film, creating the SPC flooring.