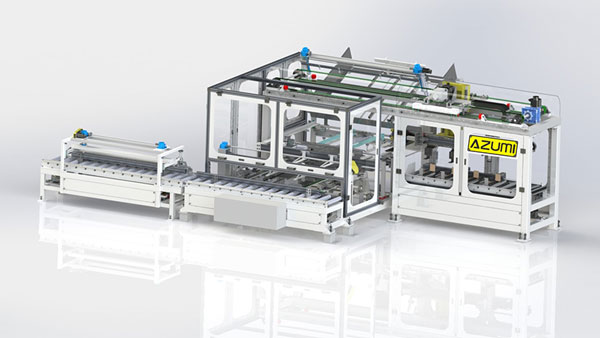

SPC Flooring Production Line

AZUMI SPC flooring production line utilizes fully automated equipment from mixers to extruders, calenders, coolers, and cutter, to auto manipulator of the finished flooring. The resulting product has no formaldehyde and is resistant to mildew, moisture, fire and insect damage and comes in a variety of options for style and color. It is perfect for indoor floors of hotels, hospitals, malls and other public locations.

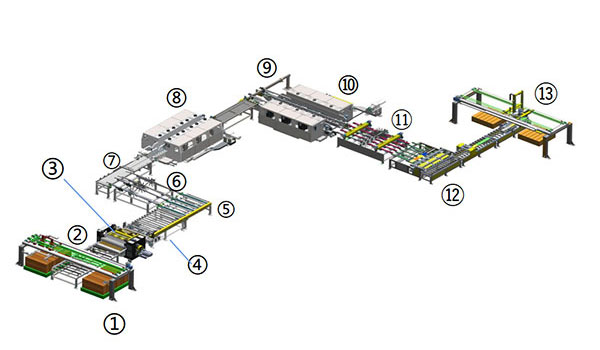

- 01Auto Loading Manipulator

- 02Inclined Roller Conveyor

- 03Multi-blade Panel Saw

- 04Roller Conveyor

- 05Right-angle Conveyor

- 06Flipper Conveyor

- 07Longitudinal Belt Conveyor

- 08Longitudinal Profiling Machine

- 09Belt Conveyor

- 10Cross Profiling Machine

- 11Flipping Ash-brush Machine

- 12High-Speed Stacking Machine

- 13Auto Stacking Manipulator