Products

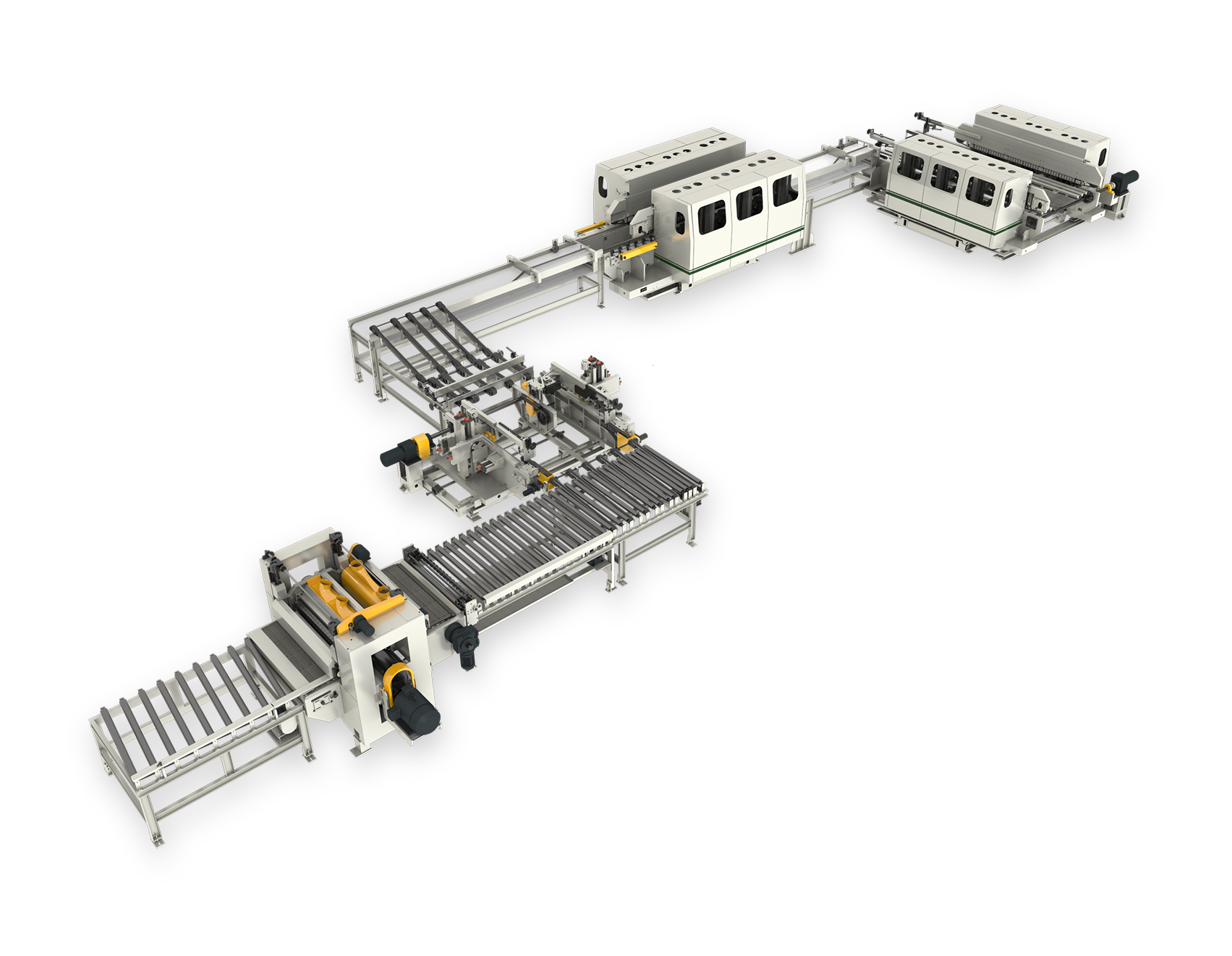

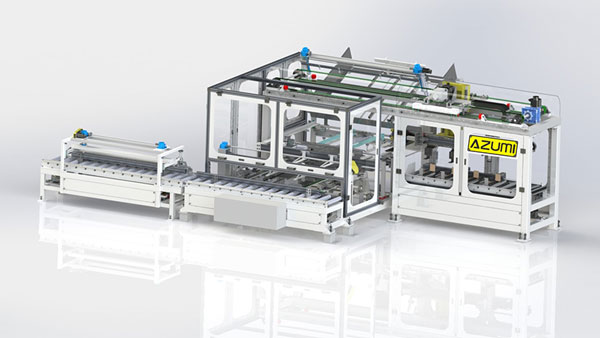

The SPC flooring manufacturing turn-key solution comprise of pressing and lamination, creating the end product in one cycle.

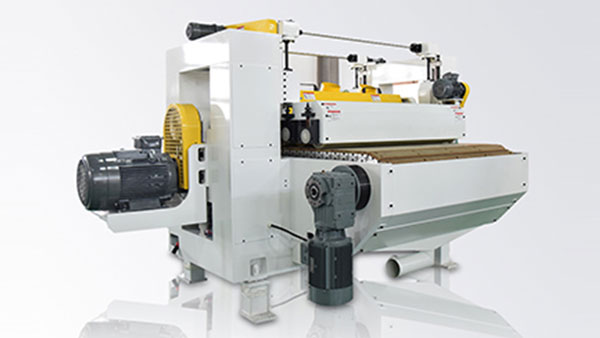

AZUMI manufactures and sells flooring and wallboard tenoners. Our state-of-the-art production lines comprise of a wide range of solutions from mixing, extruding, UV surface treating, slitting, profiling, online lubricating, flapping, brushing, acoustic backing laminating, and automatic packaging. We also have production lines for wallboard sawing and tenoning.