Digital Memory System of Floor Click Profiles

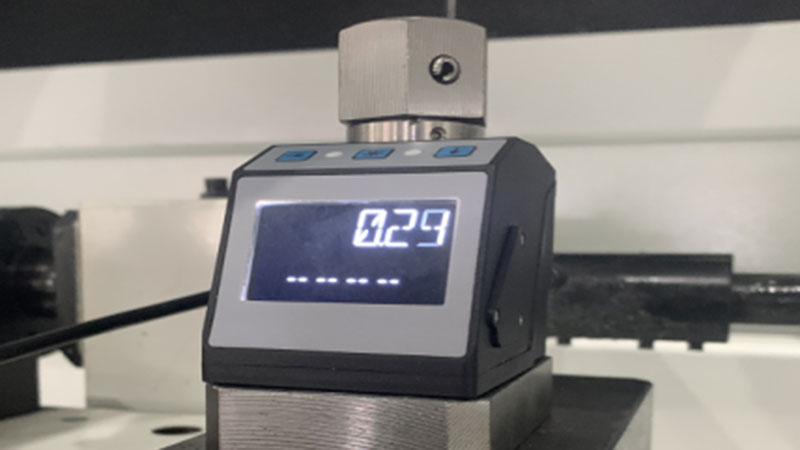

The computer system is used to enable data communication, consisting of the host computer, a high-precision vertical and horizontal transmission device, and an electronic digital display. The system stores a number of floor click profile position records. After the initial adjustment is completed, the system records its data. Subsequent switching and tool changing are all managed by the system. Finally, profile projection fine adjustment concludes the process.

Advantages

- Cost reduction through labor efficiency: one operator can manage and operate two to three machines simultaneously.

- Decreasing workload: lessen the burden on the user by lightening the amount of labor.

- Reduce the duration: reduce the adjustment time by over 60%, from 3-6 hours to approximately 1 hour.

- The system contains data that can assist when making adjustments; straightforward fine-tuning with the supplied reference mark.

Automatic Blade Adjustment System

This automatic blade adjustment system is made up of a motion control unit and a configuration interface unit. Through the application of a servo motor, driver and configuring software, the click type automatically adjusts. Customers just need to upload the profile plan, input details such as blank size, net size of the plate, space coordinate system's tool position and angle, and the system can take care of the rest, successfully achieving automatic sizing, width alteration and tool space positioning.

Advantages

- Intelligent automation aims to reduce the amount of skill needed by adjusting tools easily to create efficient and accurate results.

- Save manpower and time cost